Sealing Gasket for Chemical Fiber Industry

Gaskets

Gaskets are made of materials such as aluminum, copper, or stainless steel, which is placed between two planes to strengthen the seal, and is a sealing element arranged between the static sealing surfaces to prevent fluid leakage.

Aluminum Gaskets

Various types of aluminum materials are processed into gaskets of different shapes.

Classified according to the shape of gaskets: round, rectangular, bowl-shaped, semi-circular, waist-shaped, special-shaped.

Classified according to the surface treatment of gaskets: chrome plating, anodizing.

★ Different sizes and shapes can be processed according to customer requirements.

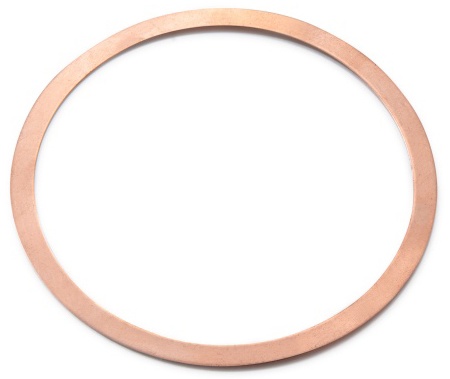

Copper Gaskets

Various copper and alloys are processed into gaskets of different shapes and specifications.

Classified according to the shape of gaskets: round, rectangular, bowl-shaped, semi-circular, waist-shaped, special-shaped.

Classified according to the surface treatment of gaskets: chrome plating, nickel plating.

★ Different sizes and shapes can be processed according to customer requirements.

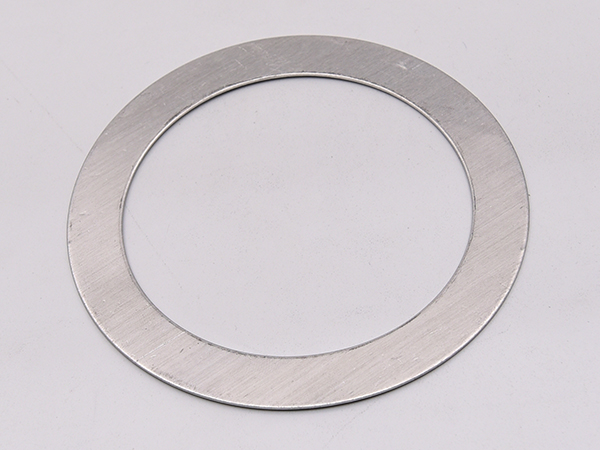

Stainless Steel Gaskets

Stainless steel material is processed into gaskets of different shapes and specifications.

Classified according to the shape of gaskets: round, rectangular, semi-circular, waist-shaped, special-shaped.

Different sizes and shapes can be processed according to customer requirements.

PTFE Gaskets

PTFE gasket or teflon gasket has good properties such as corrosion resistance, aging resistance and non-conductivity. It is widely used in petroleum, chemical, pharmaceutical, electric power, steel and other industries. Applicable media include almost all chemical components such as water, oil, acid solution, alkali solution, etc.

According to the different fillers added: no filler, glass fiber, carbon fiber, graphite, etc.

Different shapes and sizes can be processed according to customer requirements.

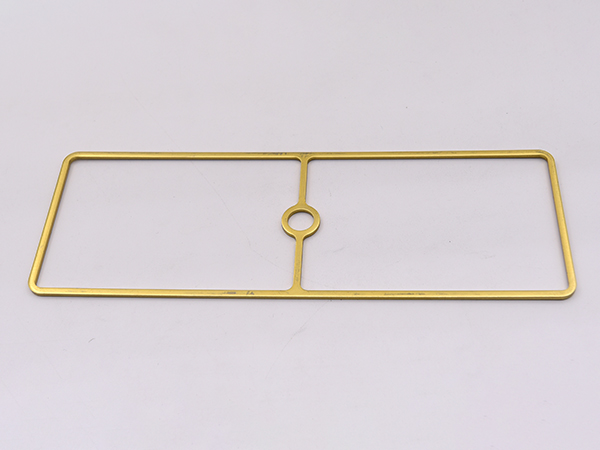

Metal Sealing Rings

The metal hollow sealing ring is formed by bending metal pipes to the required status and size, and the two ends are butt welded and polished. Its hollow structure is mainly used to regulate the pressure inside the pipe and improve sealing performance. Due to its special structure and materials, it is particularly suitable for high temperature, high pressure, low temperature, high vacuum and other working conditions that other sealing components are difficult to achieve.

Classified by the shape of sealing ring:round, rectangular, waist-shaped ,etc.

Classified by the material: copper tube, stainless steel tube, nickel alloy tube, monel alloy and other tube materials.

Product surface treatment: gold-plated, silver-plated, nickel-plated, etc.

Different shapes and sizes can be processed according to customer requirements.

Product Features

High temperature resistance, high pressure resistance, wear resistance, medium resistance and excellent sealing performance.

Application Fields

Petroleum, chemical industry, automobile, nuclear energy, food, medicine, etc.

More Product Display