-

Filtration System for Oil Filtration

The modernization of hydraulic technology has lead to the increasing performance parameters of hydraulic systems with ultra-high pressure, high flow rates and high precision. In order to ensure the performance and reliability of hydraulic systems, the standard for the cleanliness of fluids is getting higher and higher.

The oil filter truck developed by our company can be used not only as a special equipment for injecting new oil filtration into the hydraulic system, but also as a special equipment for pollutants in the medium of the regular filter system, which can help you to deal with the pollution of the hydraulic system better, prolong the service life of the hydraulic components, and ensure the normal operation of the system.

-

Melt Polymer Candle Filter for High Viscosity Substances Filtration

A melt polymer candle filter is a critical component used in the chemical fiber industry for filtering polymer melt. Polymer melt is the molten form of synthetic polymers, which is used to produce various types of chemical fibers like polyester, nylon, and acrylic.

The main purpose of a melt filter element is to remove impurities, such as solid particles and contaminants, from the polymer melt before it is further processed into fibers. These impurities can negatively affect the quality of the final chemical fibers and cause production issues like unevenness, defects, and reduced mechanical properties.

The melt filter element is installed in the extrusion line, where the polymer melt is forced through the filter to remove impurities. The filtered polymer melt then proceeds to the spinning process, where it is solidified into continuous filaments or staple fibers.

Regular maintenance and replacement of the melt filter element are important to ensure the continuous and efficient operation of the chemical fiber production process. This helps to avoid production downtime, improve product quality, and ensure the longevity of the filtering equipment. -

Stainless Steel Oil Filter in Metal Media

Oil filtration is the process of removing impurities and contaminants from oil, allowing it to be reused or recycled. It is commonly used in industries such as automotive, manufacturing, and power generation.

There are several methods of oil filtration, including:

Mechanical filtration: This method uses filters made of materials like paper, cloth, or mesh to physically trap and remove solid particles from the oil.

Centrifugal filtration: In this process, oil is spun rapidly in a centrifuge, creating a high-speed rotation that separates heavier particles from the oil by centrifugal force.

Vacuum dehydration: This method involves exposing oil to a vacuum, which lowers the boiling point of water and causes it to evaporate. This helps to remove water and moisture from the oil.

Oil filtration is important for maintaining the performance and lifespan of equipment that relies on oil lubrication. It helps to prevent the build-up of sludge and deposits, improves oil viscosity and thermal stability, and protects critical components from wear and damage. -

Stainless Steel Gas Filter in Metal Media

The goal of gas filtration is to ensure that the gas being processed or used is clean and free from particles, solids, liquids, and other contaminants that could degrade the quality of the gas or affect the efficiency and performance of equipment or processes it is used in.

Gas filtration can be achieved through various methods and technologies, depending on the specific requirements and the types of contaminants present. Some common techniques include:

Particle Filtration: This involves using filters to physically trap and remove solid particles and particulate matter from the gas stream. Filters can be made of materials such as fiberglass, polypropylene, or stainless steel, and are selected based on the size and type of particles to be removed.

Coalescing Filtration: This method is used to remove liquid droplets or mists from gases. Coalescing filters are designed to capture and merge small liquid droplets into larger ones, allowing them to be easily drained or separated from the gas stream.

The choice of filtration method and the specific filter media or technology depends on factors such as the gas composition, flow rate, pressure, temperature, and the desired level of filtration. -

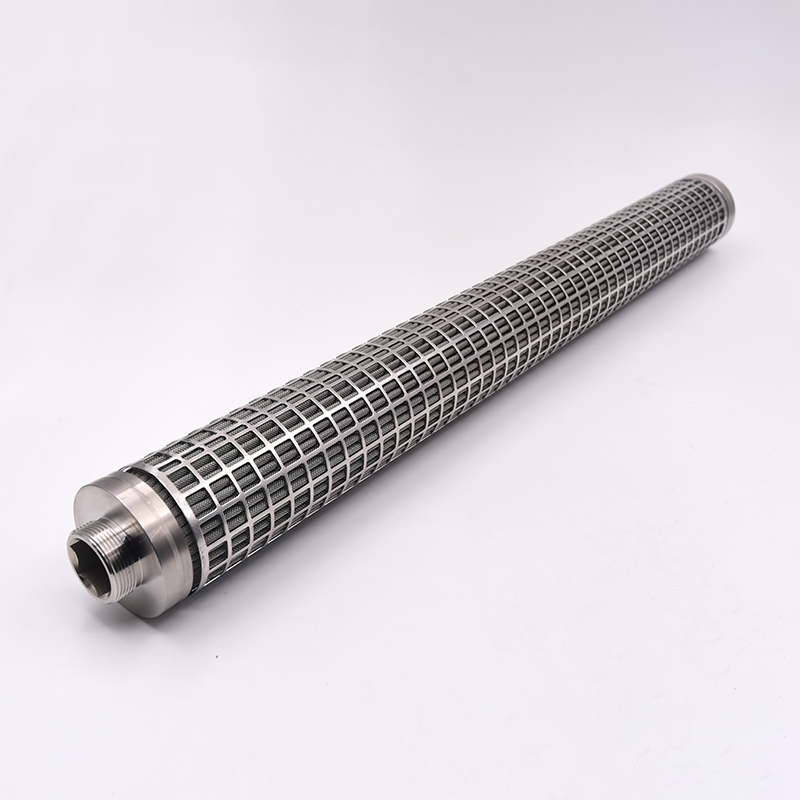

Stainless Steel Filter Cartridge

Stainless steel filter cartridge is a filter cartridge made of stainless steel material, used to filter impurities in liquid or gas. Stainless steel filter cartridges have the advantages of corrosion resistance, high temperature resistance, pressure resistance, etc., and are widely used in liquid filtration, gas filtration, solid-liquid separation and other processes in the industrial field. It can effectively remove suspended particles, impurities, sediments, etc., and improve the purity and quality of the fluid. Stainless steel filter cartridges usually have a multi-layer structure and are filled with filter media of different precisions. The appropriate filtration precision and size can be selected according to actual needs.Due to the durability and easy cleaning of stainless steel materials, stainless steel filter cartridges can be used repeatedly and have a long service life.

Stainless steel filter cartridges are widely used in chemical, petroleum, pharmaceutical, food, beverage, water treatment and other industries -

Sintered Wire Mesh Candle Filter

The sintered wire mesh filter is known for its excellent filtration efficiency, high dirt-holding capacity, and resistance to corrosion and high temperatures. It is commonly used in various industries, such as oil and gas, chemical processing, pharmaceuticals, food and beverage, and water treatment.

The filter is designed to remove impurities, solids, and contaminants from a fluid or gas stream. It can be used in both liquid and gas filtration applications, providing reliable and consistent filtration performance. The sintered wire mesh filter is capable of retaining particles down to sub-micron sizes, making it ideal for applications where fine filtration is required.

sintered wire mesh filters are highly efficient and reliable filtration solutions that provide excellent performance and long service life in a wide range of industrial applications. -

Filter Basket and Conical Filter

A filter basket is a device used for filtering solids from liquids or gases. It typically consists of a container or basket-shaped vessel with a porous material, such as a mesh or perforated metal, to trap solids while allowing the liquid or gas to flow through.

Filter baskets are commonly used in various industries, including manufacturing, oil and gas, food and beverage, and water treatment. They are often installed in pipelines or vessels to remove debris, particles, or contaminants from the fluid stream.

A conical filter is a type of filtration device that has a conical shape. It is specifically designed to filter liquids or gases and remove impurities or particles from them.

The conical shape of the filter is advantageous as it allows for efficient filtration and maximizes the surface area available for contact with the fluid. This design promotes the effective trapping or retention of particles while allowing the filtered fluid to pass through. -

Leaf Disc Filters for Polymer Film Filtration

Polymer films have a wide range of applications due to their properties and are commonly used in industries such as packaging, electronics, automotive, and biomedical as protective coatings, barrier layers, electronic device encapsulation, or as substrates for flexible displays.

As polymer film refers to a thin sheet or coating made from a polymer material. The primary purpose of leaf disc filters in polymer film filtration is to remove impurities, contaminants, and particles from the polymer melt or solution before the film formation process. This helps to ensure the production of high-quality and defect-free polymer films.

-

Metal Powder for Polymer Filtration

Metal powder available in different particle sizes made from different elements, such as nickel, chromium, silicon, Manganese has high strength and high chemical stability as filtration media during the process of polyester and polyamide yarn spinning. Futai stainless metal sand has extra irregular shape with more surface features to effectively capture and retain particles from the molten polymer in order to reduce the clog of spinnerets and yarn breakage.

The selection of stainless metal powders for polymer filtration should consider factors such as compatibility with the polymer material, the desired particle size range, filtration efficiency, and any specific chemical or environmental requirements.