Leaf Disc Filters for Polymer Film Filtration

Product Description

FUTAI filtration solutions for the polyester film process often leverage advanced proprietary technologies to optimize product consistency, enhance quality, and minimize downtime.

During the process of film production, effective filtration is extremely important. All the waste particles, such as gels and physical materials, have to be removed. Because these waste particles can cause tears, create kind of abnormalities on the surface of film. Lack of quality filtration in the continuous polyester film manufacturing process can have several negative consequences, such as frequent filter changes, decreased productivity, lower product quality.

To avoid these issues, it is crucial to invest in high-quality filtration systems that can effectively remove particles and impurities from the manufacturing process. Regular maintenance and monitoring of the filtration system can also help optimize its efficiency and reduce the need for frequent filter changes.

Our leaf disc filters are well-developed products after we are delicate to developing and improving on it for many years by using advanced professional welding equipment and process. It has the characteristics of the resistance to high pressure & temperature, to chemical corrosion; and good permeability, large dirt-holding capacity, reliable performance and long lifetime with high strength, tenacity, excellent impact resistance, and can be repeatedly used after cleaning. It is mainly used for polymer filtration in the production line of BOPA, BOPET, and BOPP, in order to remove polymer gel, coagulating agent, catalyst, and other solid impurities. Discs filters are widely applied in the industry of film, polyester polymer, spinning, packaging materials, engineering plastics, oil, chemical and others.

Technical Specifications

Working pressure: ≤31.7MPa

Working temperature: ≤300℃

Medium viscosity: ≤260Pa.s

Allowable pressure differential: ≤10Mpa

Type:

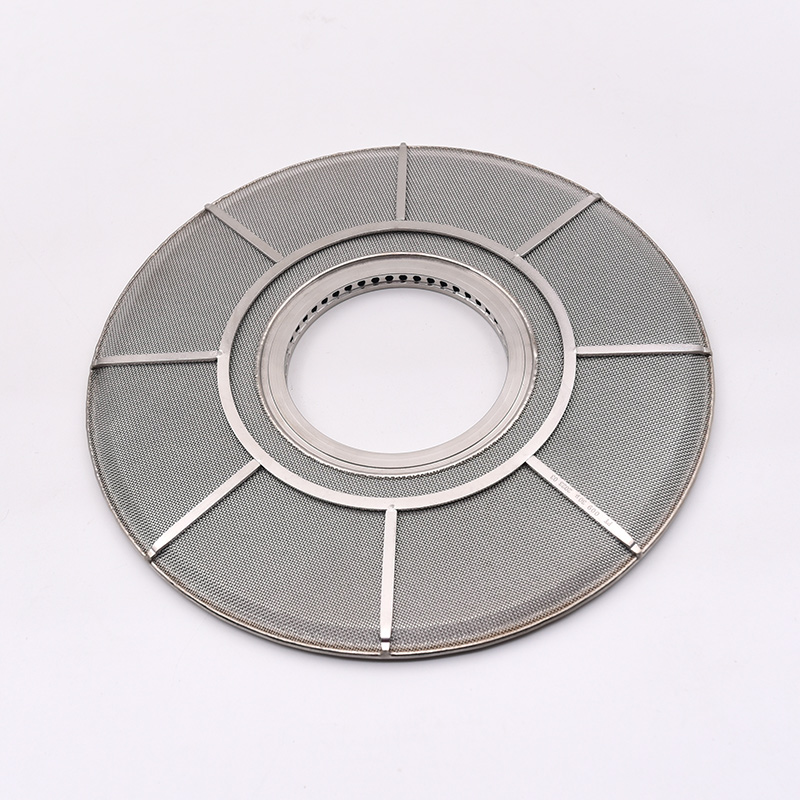

Center ring welding type(hard hub)

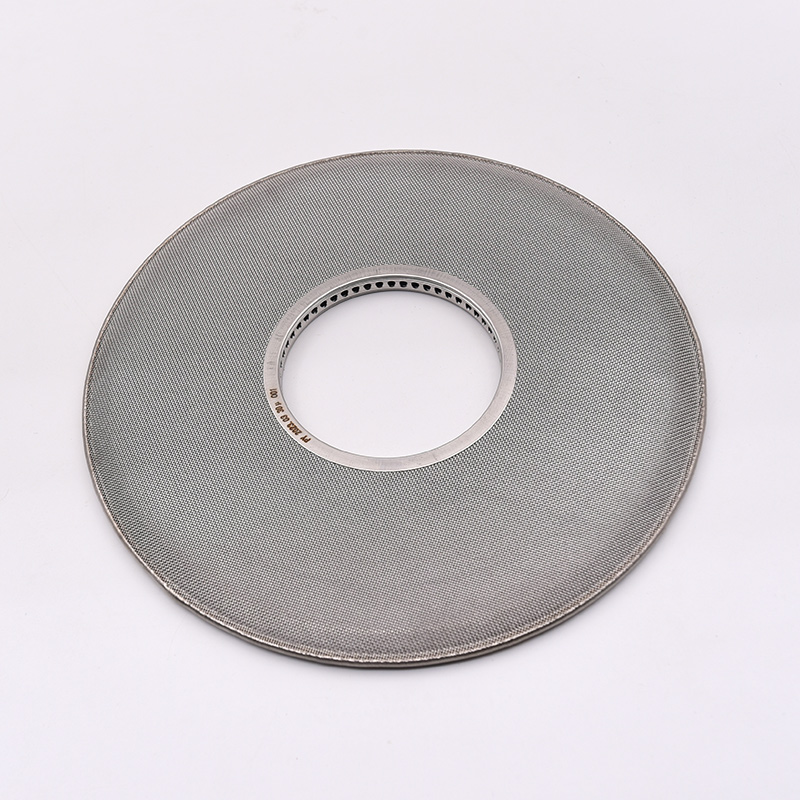

Center ring type(soft hub)

Media material:

Stainless steel sintered fiber, multi-layer sintered stainless steel wire, sintered metal powder

Filtration rate (βx≥75): 5、7、10、15、20、25、30、40、60、80、100μm

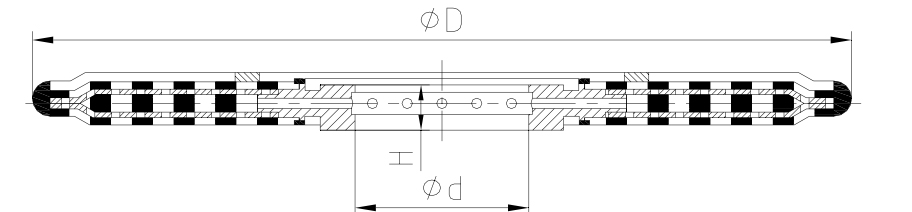

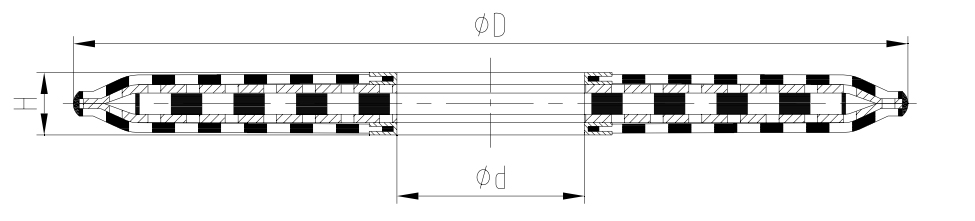

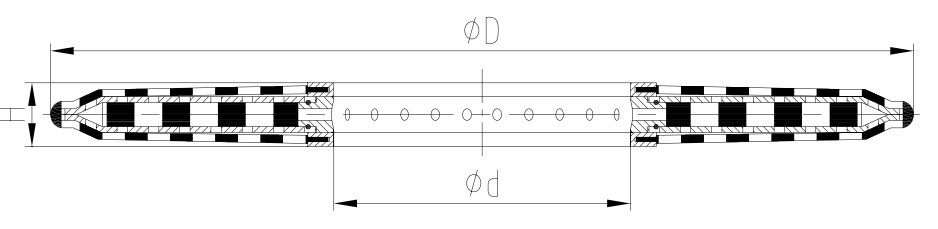

Configurations & Dimensions

| REF. NO | ΦD (mm) |

Φd (mm) |

H (mm) |

Filter Area (㎡) |

Note |

| FTD-R | Φ304.8 | Φ85 | 6.5 | 0.12 | 12 inch |

| FTD-S/233/234 | Φ304.8 | Φ63.5 | 6.5 | 0.13 | 12 inch |

| FTD-133 | Φ254 | Φ85 | 6.5 | 0.08 | 10 inch |

| FTD-179/179A/179B/179F | Φ177.8 | Φ47.6 | 6.5 | 0.04 | 7 inch |

| FTD179G | Φ254 | Φ47.6 | 7.2 | 0.082 | 10 inch |

| FTD-195/195C | Φ304.8 | Φ85 | 7 | 0.12 | 12 inch |

| FTD-195A | Φ181 | Φ85 | 8 | 0.036 | |

| FTD-195B | Φ304.8 | Φ85 | 8 | 0.12 | 12 inch |

| FTD-195H | Φ304.8 | Φ85 | 7.5 | 0.12 | 12 inch |

| FTD-195H1 | Φ297.18 | Φ85 | 7.5 | 0.11 | |

| FTD-195H2/195H3 | Φ297.18 | Φ85 | 7.8 | 0.11 | |

| FTD-199/200 | Φ222.3 | Φ63.5 | 6.5 | 0.064 | |

| FTD-202 | Φ304.8 | Φ63.5 | 7 | 0.13 | 12 inch |

| FTD-224/224A | Φ152.4 | Φ38.2 | 6.5 | 0.032 | 6 inch |

| FTD-266 | Φ177.8 | Φ85 | 6.5 | 0.029 | 7 inch |

| REF. NO | ΦD (mm) |

Φd (mm) |

H (mm) |

Filter Area (㎡) |

Note |

| FTD-P / J | Φ177.8 | Φ47.6 | 6 | 0.04 | 7 inch |

| FTD-Q | Φ177.8 | Φ63.5 | 6 | 0.04 | 7 inch |

| FTD-83 | Φ222.3 | Φ63.5 | 6.5 | 0.064 | |

| FTD-146 | Φ177.8 | Φ38.2 | 6 | 0.043 | 7 inch |

| FTD-167 | Φ304.8 | Φ63.5 | 5.5 | 0.13 | 12 inch |

| FTD-223 | Φ152.4 | Φ38.2 | 6.5 | 0.033 | 6 inch |

| FTD-261 | Φ222.2 | Φ63.5 | 6.8 | 0.06 | |

| FTD-264 | Φ304.8 | Φ85 | 6.2 | 0.12 | 12 inch |

| REF.NO | ΦD (mm) |

Φd (mm) |

H (mm) |

Filter Area (㎡) |

Note |

| FTD-164/164A/164B/164C | Φ177.8 | Φ47.6 | 10.5 | 0.04 | 7 inch |

| FTD-165 | Φ177.8 | Φ47.6 | 10.5 | 0.04 | 7 inch |

| FTD-248/248A/248B | Φ304.8 | Φ85 | 6.5 | 0.12 | 12 inch |

| FTD-248C | Φ304.8 | Φ63.5 | 6.1 | 0.13 | 12 inch |

| FTD-256 | Φ177.8 | Φ47.4 | 7.7 | 0.05 | 7 inch |

| FTD-256A/256B | Φ177.8 | Φ47.6 | 7.7 | 0.05 | 7 inch |

| FTD-257 | Φ304.8 | Φ63.9 | 7.7 | 0.14 | 12 inch |

| FTD-263 | Φ290 | Φ63.9 | 7.7 | 0.11 |