In the industries of chemical fiber and film, the melt polymer used in production often contains mechanical impurities and un-dissolved gel particles. Therefore, it is necessary to filter the melt polymer by using materials such as spin pack filter, mesh wire, candle filter, leaf disc before spinning or film production to remove impurities and improve the performance of spinning or film production. This can also prolong the lifespan of components.

In the industries of chemical fiber and film, the melt polymer used in production often contains mechanical impurities and un-dissolved gel particles. Therefore, it is necessary to filter the melt polymer by using materials such as spin pack filter, mesh wire, candle filter, leaf disc before spinning or film production to remove impurities and improve the performance of spinning or film production. This can also prolong the lifespan of components.

During the high-pressure spinning or film production process, the filter layer can create higher resistance, causing frictional heating and temperature increase in the melt polymer. This helps thoroughly mix the melt polymer and improve its rheological properties.

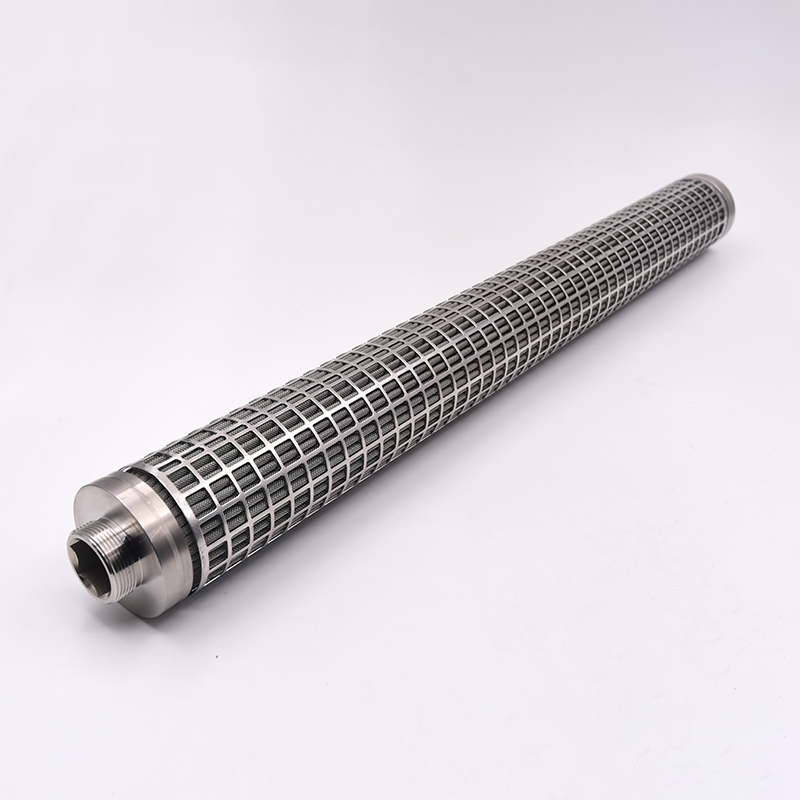

To improve the quality of spinning or film melt polymer and extend the lifespan of spinning components or leaf discs, a continuous melt filtration system (pre-filter) can be installed in the melt pipeline. This filter can remove larger particles and mechanical impurities from the melt and ensure thorough and uniform mixing of the melt. The filtration system consists of two filtering chambers and a three-way valve that connects to the melt pipeline. The three-way valve can be switched periodically to alternate between the filtering chambers, ensuring continuous filtration. The housing of the filtering chambers is cast from stainless steel. Large-area filtration system is composed of multiple candle filters. The candle filters are supported by perforated core cylinders and have single or multiple layers of metal woven meshes or sintered metal powder discs on the outer layer.

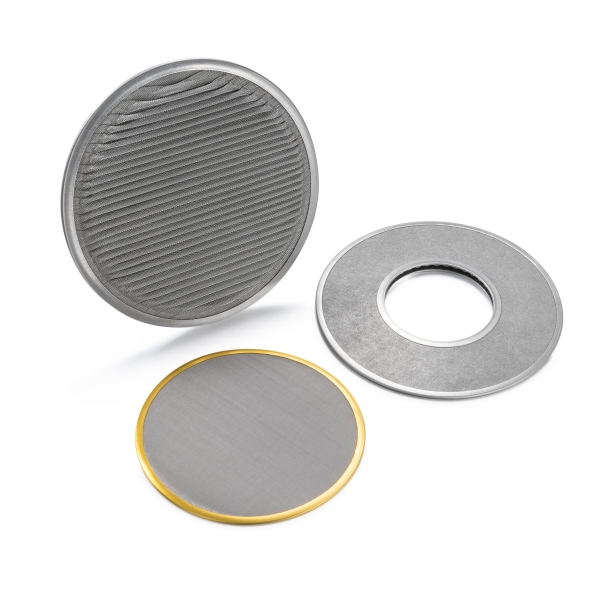

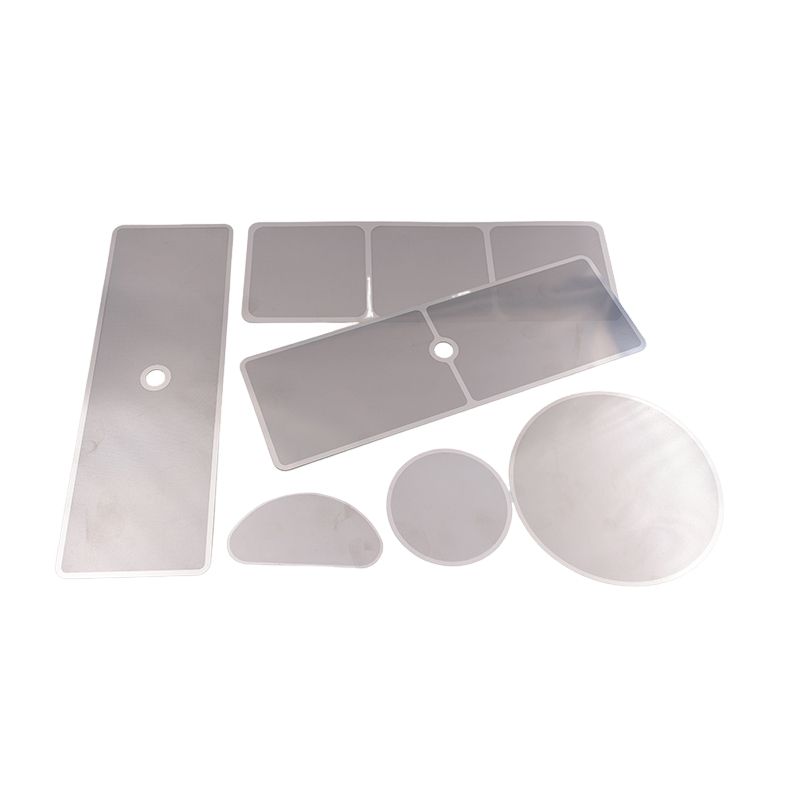

We can provide various shapes of spin pack filter, mesh wire, candle filter and leaf discs for different sizes. The filtration rate and material used can be processed according to customer requirements. We produce metal sands with different element recipe for using inside spin pack body on the chemical fiber spinning line, such as polyester and nylon. We can provide metal sands of different mesh sizes , such as 10/20, 20/30, 30/40, 40/60, 60/80, 80/100, 100/120, and 120/170 meshes.

In the production of oriented polyamide film (BOPA), oriented polyester film (BOPET), and oriented polyolefin film (BOPP), it is necessary to use disc filters to remove gels, added condensing agents, catalysts, and other solid impurities from the polymers. We can provide leaf discs of various sizes and filtration rate made from different filter materials, such as stainless steel fiber sintered felts, multi-layer stainless steel sintered meshes, or sintered metal powders.