Liquid filtration is to make the liquid containing impurities flow through the filter medium with a certain porosity, and the impurities in the liquid are trapped on the surface or inside of the medium and removed. Filtered liquids include the following products: water, chemicals, melts, beverages, wine, fuel, hydraulic oil, coolant, etc.

Liquid filtration is to make the liquid containing impurities flow through the filter medium with a certain porosity, and the impurities in the liquid are trapped on the surface or inside of the medium and removed. Filtered liquids include the following products: water, chemicals, melts, beverages, wine, fuel, hydraulic oil, coolant, etc.

Liquid filtration has emerged as an essential process in various industries, playing a crucial role in ensuring product quality and maintaining efficient operations. This filtration technique involves separating impurities, suspended particles, and contaminants from liquids, ensuring the desired level of cleanliness and purity. With an array of applications, liquid filtration has become an indispensable method to optimize processes and streamline production.

One of the primary objectives of liquid filtration is to eliminate solid particles from liquid mediums. These solid particles can be of varying sizes, ranging from visible debris to microscopic contaminants. Without effective filtration, these particles can lead to equipment clogging, product defects, and potential health hazards. Thus, liquid filtration serves as a preventive measure, safeguarding both the integrity of the product and the overall industrial processes.

In numerous industries, such as pharmaceuticals, food and beverage, chemicals, and water treatment, liquid filtration plays a crucial role in maintaining product quality. In the pharmaceutical industry, for instance, filtration is pivotal in achieving the required level of sterility and purity for drug manufacturing. Similarly, in the food and beverage industry, proper filtration ensures the removal of undesirable particles, bacteria, and microorganisms, guaranteeing a safe and healthy product for consumers.

Liquid filtration techniques primarily involve three main processes - mechanical, physical, and biological filtration. Mechanical filtration utilizes various mechanisms such as screens and meshes to physically separate particles based on their size. Physical filtration, on the other hand, employs technologies like reverse osmosis, ultrafiltration, and nanofiltration to remove impurities through selective permeation or molecular sieving. Lastly, biological filtration relies on microorganisms like bacteria to metabolize organic substances and break down complex pollutants.

The choice of liquid filtration technique depends on factors such as the nature of the liquid, the desired level of filtration, and the specific application. For instance, in water treatment plants, a combination of physical and biological filtration processes is often employed to remove both suspended solids and dissolved pollutants. In the case of industrial processes involving sensitive equipment, such as semiconductor manufacturing or research laboratories, ultrafiltration or nanofiltration techniques are used to achieve high levels of purity.

Efficiency and reliability are critical aspects of any liquid filtration system. To ensure optimal performance, regular maintenance, periodic replacement of filter media, and adherence to recommended operating conditions are vital. This not only ensures the longevity of the filtration equipment but also guarantees consistent and high-quality output. The advancements in filtration technology have also led to the development of innovative systems, such as automatic self-cleaning filters, which reduce manual intervention and enhance overall efficiency.

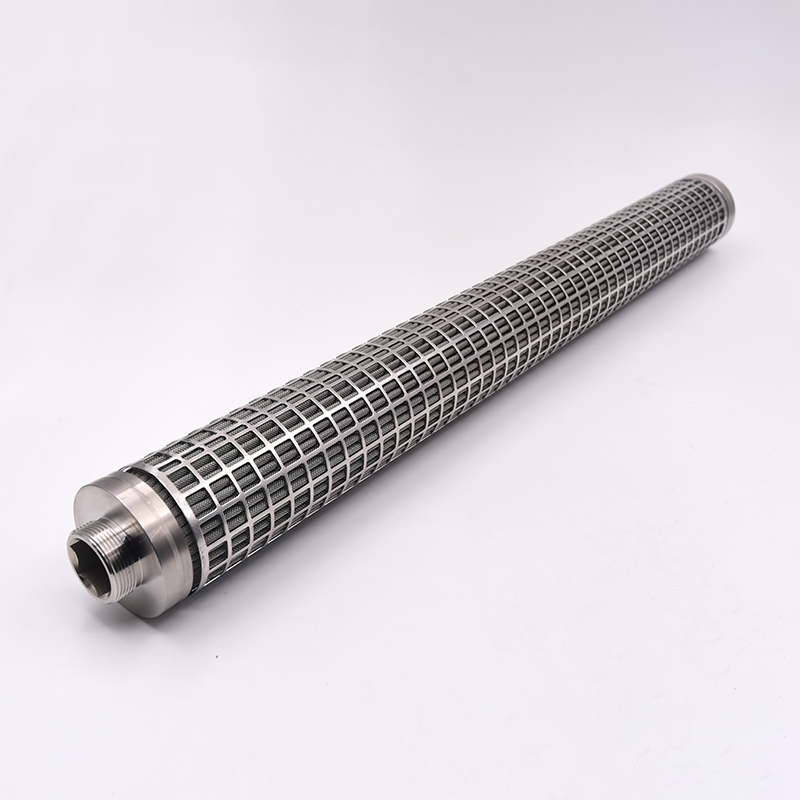

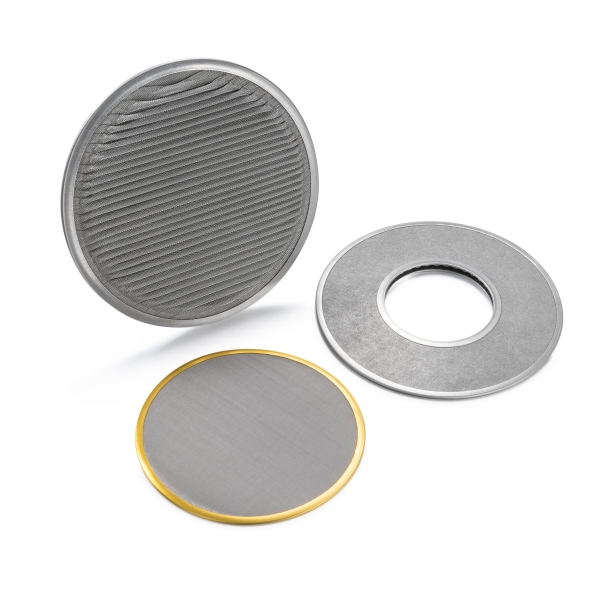

We can provide all kinds of spin pack filter, Pack screen, Pleated Candle Filter, Sintered wire mesh filter, Sintered powder candle filter, Wedge Wound Filter Element, metal sand, Leaf disc, etc. for liquid filtration. We can customize products of various specifications, sizes and filtration precision according to customer needs. The company has a wide range of products, reliable quality, high filtration efficiency, high cost performance, timely delivery and good after-sales service, which have won us praise from the industry.