Sand filtration is generally used in the petroleum industry and water treatment industry. The principle of filtering sand and gravel is mainly to use filters or filtering devices to separate sand and gravel from oil or water. The interior of the filter is usually composed of filter media, such as Johnson mesh, activated carbon, ceramics, filter screen, filter element, etc. These filter media have different pore sizes and structural forms, and can be selected according to different needs. When oil or water passes through the filter, impurities such as sand and stone are trapped on the filter medium, while clean oil or water flows out from the outlet of the filter.

Sand filtration is generally used in the petroleum industry and water treatment industry. The principle of filtering sand and gravel is mainly to use filters or filtering devices to separate sand and gravel from oil or water. The interior of the filter is usually composed of filter media, such as Johnson mesh, activated carbon, ceramics, filter screen, filter element, etc. These filter media have different pore sizes and structural forms, and can be selected according to different needs. When oil or water passes through the filter, impurities such as sand and stone are trapped on the filter medium, while clean oil or water flows out from the outlet of the filter.

Petroleum is one of the important energy sources of modern industry. However, petroleum often contains various sediments, the most common of which are sand and gravel particles. These sand particles can negatively affect the oil exploration, processing and transportation process, so filtering sand is a vital link in the oil industry.

In order to efficiently filter sand and gravel, the petroleum industry has adopted various methods and equipment. The following will introduce several common technologies and equipment for filtering sand and gravel:

Separator: A separator is a device that is often used to filter sand and gravel. It adopts the principle of physical separation, and separates sand and gravel particles from oil by means of gravity sedimentation, rotational centrifugal force or rotational potential. The working principle of the separator is to pass the oil and sand particles through the separation device inside the equipment, so that the oil can pass through smoothly, while the sand particles are separated.

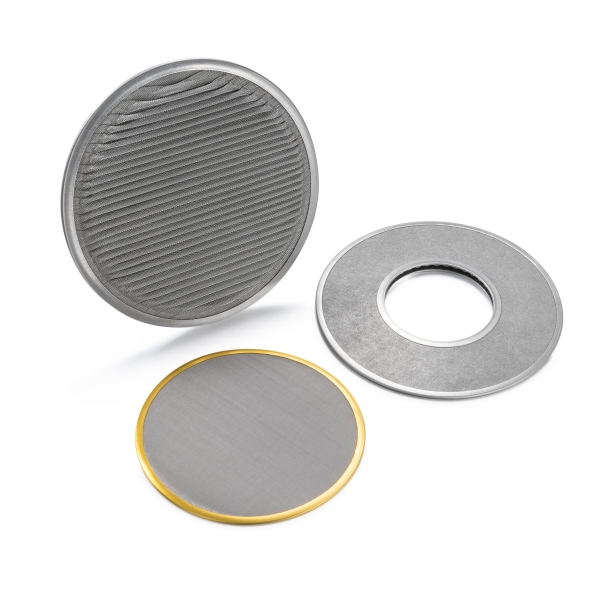

Sieves: Sieves are another common method of filtering sand and gravel. It sets a filter screen in the oil pipeline to block sand particles, allowing only oil to flow through. The filter screen can choose different filter fineness and filter material according to the needs. During use, the filter gradually accumulates sediment, so the filter needs to be cleaned or replaced regularly.

Catcher: Catcher is also one of the commonly used equipment for filtering sand and gravel. It captures and collects the sand particles in the oil by setting fishing devices. Traps typically use baskets or screens to capture the particles, which are removed by cleaning equipment. The selection and design of traps take into account the size and density of sand particles, as well as oil flow requirements.

Centrifugal filter: Centrifugal filter is an efficient device for filtering sand and gravel. It uses centrifugal force to separate the sand particles in the oil. By adjusting the rotational speed of the centrifugal filter and designing an appropriate centrifugal force, efficient sand and gravel filtration can be achieved. Centrifugal filters are often capable of handling large volumes of oil and are able to separate sand particles quickly and efficiently.

When selecting and using sand and stone filtering methods and equipment, factors such as the characteristics of oil, the size and concentration of sand and stone particles, and oil flow need to be considered. In addition, regular maintenance and cleaning of filter equipment is also very important to ensure its normal operation and filtering effect.

Filtering sand is an indispensable link in the petroleum industry. Through the reasonable selection and use of filtration technology and equipment, the quality of oil can be improved, the risk of equipment damage can be reduced, and the continuous and efficient operation of oil production can be guaranteed. Petroleum companies should pay attention to the work of filtering sand and gravel, and keep paying attention to new technologies and equipment, so as to continuously improve the filtering efficiency and effect.

Water is one of the indispensable resources in our life. However, water sources often contain various impurities, the most common and common of which are sand and stone particles. These sand particles can cause many problems to water sources, such as affecting water quality, clogging pipes, and damaging equipment. Therefore, filtering sand and gravel has become an important step in purifying water sources.

The principle of filtering sand and stone in water is based on the fact that particles with larger particle sizes cannot pass through the pores of the filter, thereby achieving the separation of water and particles. The pore size and structure of the filter determines the size and type of particulate matter that can be removed. Commonly used filter materials include quartz sand, activated carbon, ceramics, etc.

In order to effectively filter sand and gravel, we can use a variety of methods and equipment. The following will introduce several common technologies and equipment for filtering sand and stone in water:

Infiltration: Infiltration is a simple and effective filtration method. It uses multi-layer filter materials, such as quartz sand, activated carbon, etc., to filter sand and gravel particles through intermolecular adsorption and screening. In the process of Infiltration, water permeates from the upper layer and is filtered layer by layer through filter materials of different fineness. This method can effectively remove sand particles in the water, and also remove a certain amount of dissolved organic matter and microorganisms.

Sedimentation: Sedimentation is a method of settling sand particles by gravity. We can do this with sedimentation tanks or settlers. During sedimentation, water works by slowing down the flow, causing sand particles to sink due to gravity. Larger sand particles settle to the bottom quickly, while smaller particles sink slowly. By controlling the sedimentation time and the depth of the sedimentation tank, sand particles of different sizes can be removed.

Sieving: Sieving is a method of filtering sand particles through a mesh of pore size. We can place screening devices such as screens or filters in the water source. These screening devices have different sized pores to selectively filter sand and gravel particles. Large particles will be sieved out and clean water will pass through. The sieving process is simple and efficient and is usually used for the filtration of larger particles.

The importance of filtering sand and gravel cannot be overlooked. Sand particles will not only affect the transparency and taste of water, but also have adverse effects on water source systems and equipment. Sand particles can clog pipes, slow water flow, increase energy consumption, and cause wear and damage to equipment. Regular filtering of sand and gravel can not only ensure the safety and sanitation of water sources, but also prolong the service life of pipelines and equipment and reduce maintenance costs.