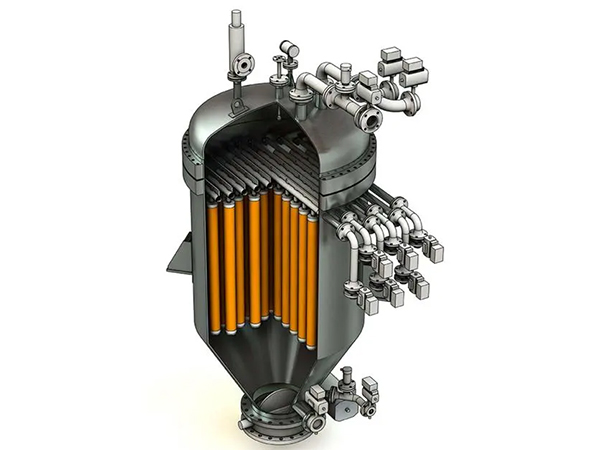

After the candle filter element is used for a period of time on the filament spinning line, it will be blocked by dirt, and the pressure difference between the inlet and outlet of the melt polymer filtration system will increase, and these pleated candle filter needs to be cleaned before it can be reused. Cleaning mainly uses physical and chemical methods to calcine, dissolve, oxidize or hydrolyze the adhered polymer at high temperature, and then perform water washing, alkali (acid) washing and ultrasonic cleaning.

After the candle filter element is used for a period of time on the filament spinning line, it will be blocked by dirt, and the pressure difference between the inlet and outlet of the melt polymer filtration system will increase, and these pleated candle filter needs to be cleaned before it can be reused. Cleaning mainly uses physical and chemical methods to calcine, dissolve, oxidize or hydrolyze the adhered polymer at high temperature, and then perform water washing, alkali (acid) washing and ultrasonic cleaning.

Cleaning methods include: calcinations method, salt bath, tri-ethylene glycol method, high temperature hydrolysis method, alumina fluidized bed method, and vacuum cleaning method. At present, the more commonly used cleaning methods are tri-ethylene glycol method, high temperature hydrolysis method, and vacuum cleaning method.

The tri-ethylene glycol method is to use the principle that the polymer can be dissolved by tri-ethylene glycol at the boiling point of tri-ethylene glycol (285°C at normal pressure) to achieve the purpose of cleaning. The cleaning step is to put the object to be cleaned into a tri-ethylene glycol tank with a heating system, raise it from room temperature to about 265°C, keep it warm for 6 hours, then let it cool down to 100°C naturally, take out the object to be cleaned, and put it in Wash it in a hot water tank at about 95°C for about 20 minutes, then soak it in a 10% NaOH solution at a temperature of 60-70°C for 12 hours, and then wash it with hot water. If it is a spinneret and a melt filter element, ultrasonic cleaning is required. The cleaning medium is pure water at a temperature of 60-70°C. The cleaning time is 15-20 minutes and finally blown dry with compressed air.

The high-temperature hydrolysis method is to use the polymer to be easily hydrolyzed and alkaline hydrolyzed at high temperature to generate low-molecular substances, so as to achieve the purpose of being removed. It is to put the object to be cleaned into the autoclave, feed steam of 0.3-0.6MPa, the temperature is about 130-160°C, and the time is 2-8 hours. In the autoclave, if a small amount of NaOH is added, the cleaning time can be shortened, and then water washing, alkali washing, and ultrasonic cleaning can be used.

The vacuum cleaning method is also called the vacuum pyrolysis method. Its working principle is to first raise the temperature to 300°C and keep it warm for a certain period of time to melt the polyester or other high polymers on the work piece to be processed, and the molten material flows out and is discharged. Then heat up, at about 350°C, the residual polyester begins to decompose, at this time, turn on the vacuum pump to evacuate, heat up to about 500°C, and keep warm. At the same time, a small amount of air is introduced to oxidize the residue. In the vacuum state, the thermal decomposition and oxidative decomposition of residual polyester are faster, and the generated gas and ash particles are sucked away to achieve the purpose of cleaning.

Post time: Aug-01-2023