How to Choose the Best Galvanized Welded Wire Mesh for Your Project

Table of Contents

- Factors to Consider When Selecting Galvanized Welded Wire Mesh for Your Needs

- Understanding Wire Gauge and Its Impact on Mesh Strength and Durability

- Key Applications of Galvanized Welded Wire Mesh in Various Industries

- Comparing Coating Techniques: Hot-Dipped vs. Electro-Galvanized Wire

- Maintenance Tips for Longevity of Galvanized Welded Wire Mesh Installations

- Cost Analysis: Finding the Best Value for Your Galvanized Wire Mesh Project

- Exploring the Versatility and Applications of Plain Weave Metal Wire Mesh in Various Industries

- FAQS

- Conclusion

- Related Posts

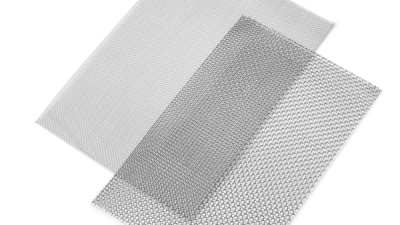

So, when you're starting a project that needs to last a long time and handle some serious wear and tear, choosing the right materials is super important. If you're thinking about galvanized welded wire mesh, you're on the right track. Did you know that the global market for galvanized wire is expected to hit around 2.4 billion USD by 2026? That’s mostly because industries like construction, farming, and filtration are really leaning into it these days.

Our team at FUTAI FILTERS DEPARTMENT — part of FUTAI MACHINERY CO., LTD. — has been a leader in filtration products since 2007. We’ve got tons of experience making top-notch metal wire cloth in various types like stainless steel 304, 316, and 316L.

But here’s the thing — picking the right galvanized welded wire mesh isn’t just about grabbing the first good-looking option. You’ve got to think about your specific project needs, the environment it'll be used in, and all the standards you need to follow. This quick guide should help clear things up so you can make a smart choice that keeps your project running smoothly and lasting for the long haul.

Factors to Consider When Selecting Galvanized Welded Wire Mesh for Your Needs

When you're picking out galvanized welded wire mesh for your project, there are a few pretty important things you’ll want to keep in mind. First off, take a look at the gauge and the thickness of the wire itself. Generally speaking, thicker wires and smaller gaps between the wires give you more strength and durability, which is especially important if you're dealing with something demanding. Also, don’t forget to check the spacing between the wires — it really affects how well the mesh can support or filter different materials.

Another thing to consider is the kind of galvanization used. Hot-dipped galvanization tends to offer better resistance against rust and corrosion compared to electro-galvanized options, so if your project’s outdoors or in a harsh environment, that might be the way to go. As someone who’s worked with a lot of these products, FUTAI MACHINERY CO., LTD. is a trusted name in the industry. They’ve got tons of experience making high-quality galvanized welded wire mesh, and their products can be customized to match a variety of needs. Whether you need something super strong or just the right size for filtration, they’ve got options like stainless steel 304, 316, or 316L — so you’re pretty much covered for whatever project you’re tackling.

Understanding Wire Gauge and Its Impact on Mesh Strength and Durability

Hey, when you're picking out the best galvanized welded wire mesh for your project, understanding wire gauge is pretty important. Basically, wire gauge tells you how thick the wire is—that’s what affects how strong and durable the mesh will be. A lower gauge number means thicker wire, which usually translates to a sturdier, more resistant piece. For example, if you’re working on something that needs to hold up tough—like fencing or reinforcement—going with a lower gauge mesh can give you that extra strength to handle different weather conditions or stresses.

At FUTAI MACHINERY CO., LTD., we’ve got plenty of experience making filtration products, including top-notch metal wire cloth. We offer various materials like stainless steel 304, 316, and 316L, all available in different wire gauges. Picking the right mesh really depends on what you’re doing and what kind of strength and longevity you need. Once you get a handle on how wire gauge impacts performance, you’ll be able to make smarter choices tailored to your project’s unique needs, making sure everything works smoothly and lasts long-term.

Key Applications of Galvanized Welded Wire Mesh in Various Industries

Galvanized welded wire mesh is pretty much a go-to material in a bunch of different industries, and it’s not hard to see why—it's tough and resistant to rust. You often find it in construction sites, where it acts as reinforcement for concrete structures. Believe it or not, a report from Frost & Sullivan predicts that the global demand for construction wire mesh could hit around $2.5 billion by 2025. That just shows how crucial this mesh is when it comes to making sure buildings and structures stay strong and safe.

On the farm side of things, this mesh is a real lifesaver for fencing and keeping animals contained. It’s super durable, which is key for protecting crops and livestock alike. According to the Agricultural Market Opportunities report, the market for agricultural fencing is expected to grow at about 4.5% annually through 2026, thanks to the rise in sustainable farming methods. Plus, galvanized welded wire mesh isn’t just for buildings and farms—it’s also used in making safety barriers and gates, especially in industrial settings where safety is a big deal. All in all, these different uses really highlight how important it is to pick the right kind of galvanized welded wire mesh for whatever project you’re working on—whatever industry you’re in, really.

Comparing Coating Techniques: Hot-Dipped vs. Electro-Galvanized Wire

When you're picking out galvanized welded wire mesh for your project, it’s pretty important to understand the difference between hot-dipped and electro-galvanized coatings. Basically, hot-dipped galvanization means dipping the wire into molten zinc—sounds simple enough, but it actually creates a much thicker, more durable coating that’s great at resisting rust and corrosion. This makes it a solid choice if you're dealing with outdoor or tougher environments because that heavy zinc layer can hold up pretty well over time, keeping things protected and long-lasting.

Now, on the flip side, electro-galvanized wire gets its zinc coating through an electroplating process. The coating there is thinner, so while it does offer some decent protection against rust, it’s probably not going to cut it in really harsh conditions. This type works better indoors or in places where moisture isn’t a constant problem. Knowing the ins and outs of these coating methods can really help you pick the right wire mesh for your needs — whether you want something rugged and durable or just enough protection for lighter, indoor use. Bottom line: understanding these differences makes all the difference when it comes to making sure your project lasts and performs like a champ.

Comparison of Coating Techniques for Galvanized Welded Wire Mesh

This chart compares the performance of Hot-Dipped Galvanized and Electro-Galvanized welded wire mesh across various dimensions including corrosion resistance, coating durability, cost, application versatility, and weight. The data presented can help in making an informed decision based on project requirements.

Maintenance Tips for Longevity of Galvanized Welded Wire Mesh Installations

When you think about how long galvanized welded wire mesh setups last, one thing that really makes a difference is maintenance. Keeping an eye on things with regular inspections is pretty much essential — you want to catch any signs of wear or damage before they become big problems. Interestingly, industry studies show that about 20% of fencing failures happen because of neglect or poor upkeep, which obviously affects both how well the fence works and how long it lasts. Making sure your wire mesh is clear of debris and not showing any rust is a simple way to keep it in good shape. Doing a quick check every six months can really stretch its lifespan and save you headaches down the road.

Oh, and if you're dealing with smaller livestock, galvanized welded wire fencing is hands-down a solid choice because of its strength and flexibility. Recent reports highlight that this kind of fencing not only provides great security but can also be adapted to a bunch of different setups — which is super handy when managing animals. Putting a protective coating on the wire now and then is also worth it; it prevents rust and can even extend the life of your fence by up to 50%. That’s a pretty good investment, especially if you care about how things look and work. Plus, with companies like FUTAI MACHINERY CO., LTD. offering top-quality wire products, choosing the right materials and sticking to simple maintenance tips can help ensure your galvanized wire mesh lasts a long time and keeps doing its job.

In a nutshell, staying on top of maintenance isn’t just a chore — it’s the secret to making sure your fencing stays reliable and durable for years to come.

Cost Analysis: Finding the Best Value for Your Galvanized Wire Mesh Project

Starting a galvanized wire mesh project? One of the big things you’ll want to get a handle on is the costs involved — it really pays to understand where your money’s going so you can make the most of your budget. The price of galvanized welded wire mesh can vary pretty widely, depending on stuff like the material, mesh size, and how thick the coating is. From what I’ve seen industry reports, prices generally range from about 50 cents all the way up to three bucks per square foot, depending on these factors. If you’re working on a bigger project, it’s definitely worth sourcing from a reliable manufacturer — companies like FUTAI MACHINERY CO., LTD., who’ve been around since 2007. They’ve got loads of experience making high-quality filtration products and wire cloth, so you’re pretty much guaranteed to get durable materials that strike a good balance between cost and performance.

Here’s a quick tip: think about what your project specifically needs — like, how much weight the mesh should support or environmental stuff like corrosion resistance. Good quality galvanized wire isn’t just about preventing rust; it can also make your project last way longer, saving you money in the long run. And don’t forget, comparing different suppliers will help you find the best prices without sacrificing quality.

Another thing to keep an eye on is the wire gauge and the spacing of the mesh — these little things really affect how strong the mesh is and what it costs. Making a smart, informed choice here can cut costs and ensure you get a product that actually works for what you need. Bottom line: investing in good materials from a reputable place like FUTAI pays off over time, giving you peace of mind and better results.

How to Choose the Best Galvanized Welded Wire Mesh for Your Project - Cost Analysis: Finding the Best Value for Your Galvanized Wire Mesh Project

| Mesh Size (Inches) | Wire Diameter (Gauge) | Sheet Size (Feet) | Price per Sheet ($) | Ideal Use |

|---|---|---|---|---|

| 1x1 | 14 | 4x50 | 75 | Animal Enclosure |

| 2x2 | 16 | 3x50 | 50 | Garden Fencing |

| 1x2 | 12 | 4x100 | 120 | Outdoor Trellis |

| 2x4 | 10 | 6x10 | 95 | Construction and Support |

| 3x3 | 14 | 5x100 | 130 | Security Fencing |

Exploring the Versatility and Applications of Plain Weave Metal Wire Mesh in Various Industries

Plain weave metal wire mesh is celebrated for its versatility and strength, making it an essential component in various industrial applications. The weaving technique involves interlacing wires in a straightforward crisscross pattern, which not only enhances durability but also contributes to uniform aperture sizes. According to a recent report by MarketsandMarkets, the global metal mesh market is projected to reach $1.7 billion by 2026, underscoring the growing demand for reliable filtration and screening solutions across multiple sectors.

One of the key advantages of plain weave metal wire mesh is its high flow rate and visibility, making it ideal for applications requiring effective filtration without compromising on visibility. Industries such as food processing, pharmaceuticals, and construction utilize this type of mesh for various purposes, including insect screens, reinforcement, and screening materials. A study published in the Journal of Industrial and Engineering Chemistry highlighted that materials like stainless steel and aluminum are preferred for their strength and resistance to corrosion, further broadening the usability of plain weave metal wire mesh in critical environments.

When selecting plain weave metal wire mesh, it is crucial to consider factors like wire gauge, mesh size, and the specific material type. These elements play a significant role in ensuring that the mesh meets the unique requirements of each application. The versatility of plain weave metal wire mesh not only meets the technological demands of today’s industries but also aligns with environmental considerations, reinforcing its position as a go-to solution for a wide range of industrial needs.

FAQS

: You should consider the gauge and wire diameter, the spacing between wires, and the type of galvanization used. Thicker wires and smaller openings offer greater strength, while the spacing influences filtration and support capabilities.

Hot-dipped galvanization provides a thick, resilient coating through immersion in molten zinc, ensuring superior corrosion resistance for harsh environments. In contrast, electro-galvanized wire has a thinner zinc layer, suitable for indoor use or areas with minimal moisture exposure.

Thicker wires and smaller openings provide greater strength and durability, making them suitable for demanding applications and enhancing the overall effectiveness of the mesh.

The spacing impacts the mesh's ability to filter or support various materials effectively, influencing its performance in specific applications.

Hot-dipped galvanization is preferable for outdoor or harsh environments due to its superior corrosion resistance, ensuring longevity and durability.

Yes, galvanized welded wire mesh can be made from various materials, including stainless steel 304/316/316L, allowing for customized options based on strength and filtration efficiency needs.

When selecting mesh for filtration, consider the wire gauge, spacing, and material to ensure adequate strength and effectiveness in filtering the intended materials.

Conclusion

When you're trying to pick out the best galvanized welded wire mesh for your project, there are a few things you really wanna keep in mind to make sure it performs well and lasts. Understanding wire gauge is super important because it truly affects how strong and durable the mesh will be over time. Different industries use this type of mesh for all sorts of purposes — from fencing farms and gardens to construction sites and filtering stuff. Plus, comparing different coating methods, like hot-dipped versus electro-galvanized wire, can make a real difference in how well it resists rust and how long it stays in good shape.

Taking care of your mesh isn’t just a one-time thing — regular checks and proper maintenance can really extend its lifespan and keep it looking and working great. And of course, don’t forget about doing a quick cost rundown to find that sweet spot between quality and affordability. Here at FUTAI Machinery Co., Ltd., we’ve got years of experience behind us, so we’re confident in offering top-notch metal wire cloth, including galvanized options. We’re all about making sure our customers end up with the best products for whatever they’re working on.

Related Posts

-

10 Essential Benefits of Pre Filter Candle: Enhance Your Air Quality Management Strategy

-

Top Strategies for Sourcing Efficient Barmag Pack Filters in the Textile Industry

-

Envisioning Tomorrow: The Evolution of Extruder Technology in Manufacturing Process

-

5 Essential Tips for Choosing the Right Pack Filter for Your Business

-

5 Best Reasons to Choose Mesh Pack for Your Business Needs

Blog Tags: