5 Essential Tips for Choosing the Right Pack Filter for Your Business

Table of Contents

- Understanding Your Business Needs: Key Considerations for Filter Selection

- Types of Pack Filters: Matching Solutions to Specific Applications

- Evaluating Filter Efficiency: Metrics to Guide Your Decision

- Budgeting for Quality: Balancing Cost and Performance in Filter Choices

- Maintenance and Replacement: Ensuring Longevity of Your Pack Filters

- Supplier Reliability: Choosing a Trusted Partner for Your Filter Needs

- Maximizing Efficiency in Filtration Processes: Insights from Recent Industry Reports on Metal Media Performance

- FAQS

- Conclusion

- Related Posts

Nowadays, in the world of industry, choosing the right Pack Filter is more important than ever. It’s a key part of keeping things running smoothly and making sure your product stays top-notch. I recently came across a market report that estimates the global filtration industry will hit around USD 44 billion by 2025. That just shows how vital filtration solutions have become across all kinds of sectors. At FUTAI MACHINERY’s FILTERS DEPARTMENT—founded back in 2007—our team brings years of hands-on experience to the table, especially when it comes to making high-quality filtration products like stainless steel wire cloths (think grades 304, 316, or 316L). The right Pack Filter doesn’t just improve fluid filtration; it can make a real difference in your overall productivity and help you stay compliant with industry standards. That’s why it’s so important to understand what makes a Pack Filter suitable for your specific needs—so you can stay competitive in this fast-changing market. Trust me, getting this right can really give your business the edge it needs!

Understanding Your Business Needs: Key Considerations for Filter Selection

When you're trying to pick the right filter for your business, really taking the time to understand what you need is super important. Every industry has its own quirks—things like what you're filtering and what results you want to see. For example, if you’re working with corrosive stuff, you’ll probably want filters made from tougher materials like 316L stainless steel, which can stand up better to harsh conditions. By taking a good look at what kinds of materials and contaminants you're dealing with, you can choose a filter that actually does the job well.

Beyond the material itself, it’s also smart to think about the environment where the filter will be used. Things like temperature, pressure, and flow rate really play a role in how long the filter will last and how well it performs. At FUTAI MACHINERY CO., LTD., we specialize in making a wide range of filtration products customized to match these specific needs. Getting a handle on these factors not only boosts efficiency but also makes your operation safer and more reliable. Ultimately, the goal is to have a filtration system that really supports your business efforts without any surprises down the line.

Types of Pack Filters: Matching Solutions to Specific Applications

When you're choosing pack filters for your business, it’s pretty important to get a good handle on the different types out there and what they’re actually used for. For example, in industrial environments, HEPA filters are a common go-to—they trap airborne particles really well, up to 99.97% efficiency for particles as tiny as 0.3 microns. That kind of filtration is a big deal, especially in industries like pharmaceuticals and food processing, where keeping things super clean and air quality top-notch isn’t just a preference, it’s a must.

Then, there’s activated carbon filters, which are mainly used to knock out odors and VOCs—volatile organic compounds. Industry reports suggest that the market for air filters is expected to grow like crazy, especially with HVAC systems increasingly using these techs to improve indoor air quality. As regulations get tighter and customer expectations around air purity rise, picking the right pack filter that matches your operational needs and complies with standards really becomes essential. Plus, with all the cool advancements in smart filtering tech, businesses now have options like systems that adapt based on real-time environmental data—pretty neat, right? It’s all about making sure your air quality keeps up with modern demands while staying efficient and reliable.

Evaluating Filter Efficiency: Metrics to Guide Your Decision

When you're trying to pick out the right filter for your business, it's super important to consider how effective it is. I mean, looking at key things like dust holding capacity (DHC), airflow resistance, and the ability to trap tiny particles really helps you get a sense of how well it’s gonna perform. According to a report from the American Industrial Hygiene Association (AIHA), filters with a high DHC can seriously last longer—like, potentially cutting down on replacement costs by up to 30%. That means not only do you save money, but you also keep things running smoothly without too much downtime for maintenance.

And let’s not forget about airflow resistance. It’s a big deal. A study by the National Air Filtration Association (NAFA) shows that filters with lower resistance to airflow can boost your system’s efficiency and even save you around 15-20% on energy bills. This is especially huge if your business depends on HVAC systems since energy costs can really add up. Oh, and don’t overlook particle size capture—filters that trap even tiny particles (down to 0.3 microns) help improve air quality, which is especially important if you work in fields like pharma or food processing. Picking the right filter with these factors in mind isn’t just about following standards; it’s about making sure your operation runs at its very best.

Budgeting for Quality: Balancing Cost and Performance in Filter Choices

When you're picking out a pack filter for your business, it's really important to think about quality and budget at the same time. Sure, going for the cheapest option might seem like a good idea at first, but investing in a decent, reliable filter can save you money in the long run. It often means fewer repairs, less downtime, and overall better performance, which adds up. Sometimes, it’s tempting to grab the low-cost filter, but you gotta ask yourself—how well does it work under different conditions? Will it last? Those are key questions if you're really after the best bang for your buck.

One thing I always recommend is taking a close look at what your business actually needs before making a choice. Think about what kind of contaminants are popping up in your environment, and how effective the filter needs to be. That way, you won’t waste cash on features that you don’t really need. Honestly, finding the right balance between cost and performance is kinda essential. Yeah, a high-quality filter from a trusted brand might cost a bit more upfront, but in the long run, the improved efficiency and fewer headaches can save you a ton on your operating costs.

And don’t forget to check out what other customers are saying and do some research on the different options out there. Making an informed decision means you’re more likely to get something that ticks all your boxes in terms of performance and price. All in all, just take your time, weigh your options, and pick a filter that really fits your needs without sacrificing quality. You’ll thank yourself later!

5 Essential Tips for Choosing the Right Pack Filter for Your Business - Budgeting for Quality: Balancing Cost and Performance in Filter Choices

| Filter Type | Initial Cost ($) | Replacement Frequency (Months) | Average Lifespan (Months) | Efficiency (%) |

|---|---|---|---|---|

| HEPA Filter | 150 | 6 | 24 | 99.97 |

| Activated Carbon Filter | 80 | 4 | 12 | 85 |

| Electrostatic Filter | 100 | 3 | 18 | 95 |

| Pleated Filter | 50 | 2 | 6 | 90 |

| Washable Filter | 120 | 12 | 60 | 80 |

Maintenance and Replacement: Ensuring Longevity of Your Pack Filters

When you're dealing with pack filters, keeping up with proper maintenance and replacing them on time is key to making sure everything runs smoothly in your business. It’s a good idea to set aside some regular time for inspections—this way, you can catch any signs of wear and tear early on. Keep an eye out for things like dirt buildup or changes in airflow, which are pretty good indicators that something needs attention. Also, having a cleaning schedule not only helps your filters last longer but can also improve air quality and make your equipment work more efficiently.

And don’t forget about replacing those filters! Even the best ones don’t last forever. Running your system with a clogged or outdated filter can jack up your energy bills and even slow down productivity. To avoid that, it’s smart to monitor how often you’re using them and check their condition regularly to know exactly when it’s time for a swap. Putting these simple maintenance steps into practice will help your pack filters perform at their best and give your business environment a nice boost.

Pack Filter Maintenance and Replacement Frequency

Supplier Reliability: Choosing a Trusted Partner for Your Filter Needs

When you're picking out a pack filter for your business, one of the most important things to keep in mind is how reliable your supplier is. A trustworthy partner isn’t just about getting good quality products—they also support you throughout the whole process, even after the sale. Building a solid relationship with a dependable supplier can really pay off, giving you access to the latest in filtration tech and making sure you’re set up to handle your specific operational needs without a hitch.

If you’re wondering how to tell if a supplier’s reliable, a good start is to do some homework on their reputation in the industry. Look for folks with a proven track record when it comes to consistent quality, on-time deliveries, and customer service that actually responds when you need help. Customer reviews and case studies are pretty helpful—they give you a real sense of how committed they are to doing a good job. And don’t hesitate to reach out directly to chat about your expectations and what you’re looking for. Often, that kind of open talk can help you spot the suppliers who truly care about helping your business succeed. Putting reliability first means your filtration needs will get sorted out smoothly, so your business can run without a bunch of headaches.

Maximizing Efficiency in Filtration Processes: Insights from Recent Industry Reports on Metal Media Performance

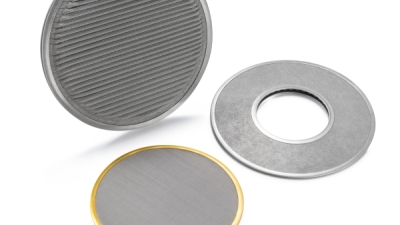

In the pursuit of maximizing efficiency in filtration processes, recent industry reports have spotlighted the remarkable performance of metal media in spin pack filters. These filters play a crucial role in various sectors, especially in polymer manufacturing, where the integrity of the final product hinges on the purity of the substances used. The versatility of metal wire mesh allows these filters to be fabricated into multiple shapes—cylindrical, rectangular, or even custom designs—ensuring a perfect fit for any filtration system.

Metal media filters are adept at handling diverse solutions, including oil, gas, water, grease, and liquid polymers, regardless of temperature. Their robust construction enables them to endure challenging environments, characterized by high temperatures and pressures. By effectively removing impurities and particulate matter, these filters not only enhance product quality but also contribute to streamlined operations and reduced downtime. The latest insights from the industry underline that investing in high-performance metal media filters is a pivotal step for manufacturers aiming to optimize their filtration processes and achieve superior results.

FAQS

: Understanding specific business needs is crucial because each industry has unique requirements based on the types of substances being filtered and the desired outcomes, which helps ensure a more effective filtration solution.

Businesses dealing with corrosive materials are recommended to use filters made from higher-grade stainless steel, such as 316L, which offers superior resistance to harsh environments.

Important factors to evaluate include temperature, pressure, and flow rate, as they significantly influence filter performance and longevity.

Key metrics like dust holding capacity (DHC) and airflow resistance can extend filter service life and improve system efficiency, potentially reducing costs associated with replacements and energy consumption.

Filters with a high dust holding capacity can potentially reduce replacement costs by up to 30%, enhancing operational efficiency and minimizing downtime.

Understanding airflow resistance is important because filters with lower resistance can improve overall system efficiency, leading to energy savings of around 15-20%, which is particularly beneficial in HVAC-dependent industries.

Particle size retention refers to a filter's ability to capture small particles, down to 0.3 microns, which is significant for improving air quality, especially in sectors like pharmaceuticals and food processing.

The right filter metrics ensure compliance with industry standards and enable a business to operate at maximum efficiency, enhancing safety and reliability across operations.

Conclusion

Picking out the right Pack Filter for your business is super important—and honestly, it can make a huge difference in how smoothly everything runs. Start by really figuring out what your specific needs are. Think about the kind of application you’re dealing with and what kind of fluids you’re filtering—those details matter. With so many types of Pack Filters out there, it’s a good idea to find one that fits your particular situation, so you get the best performance without any hassle.

Also, it’s worth checking out some key metrics to see how efficient different filters are—that can really help you make a smart choice. Don’t forget to strike a balance when it comes to budget, aiming for good quality but also keeping costs in check. And, of course, plan for regular maintenance and swaps—that way, your filters will last longer and keep doing their thing. Lastly, teaming up with a trusted supplier like FUTAI MACHINERY CO., LTD. can really make a difference—they’ve got the experience and top-notch products to back you up for the long haul.

Blog Tags: