Envisioning Tomorrow: The Evolution of Extruder Technology in Manufacturing Process

Table of Contents

- The Historical Context of Extruder Technology in Manufacturing

- Key Innovations in Extruder Design Over the Decades

- The Role of Digital Transformation in Extruder Efficiency

- Sustainability Trends: Eco-Friendly Extrusion Processes

- Future Prospects: AI and Automation in Extruder Technology

- Case Studies: Successful Implementation of Advanced Extruders in Industries

- Enhancing Efficiency and Longevity: The Benefits of Stainless Steel Gas Filters with Metal Media

- FAQS

- Conclusion

- Related Posts

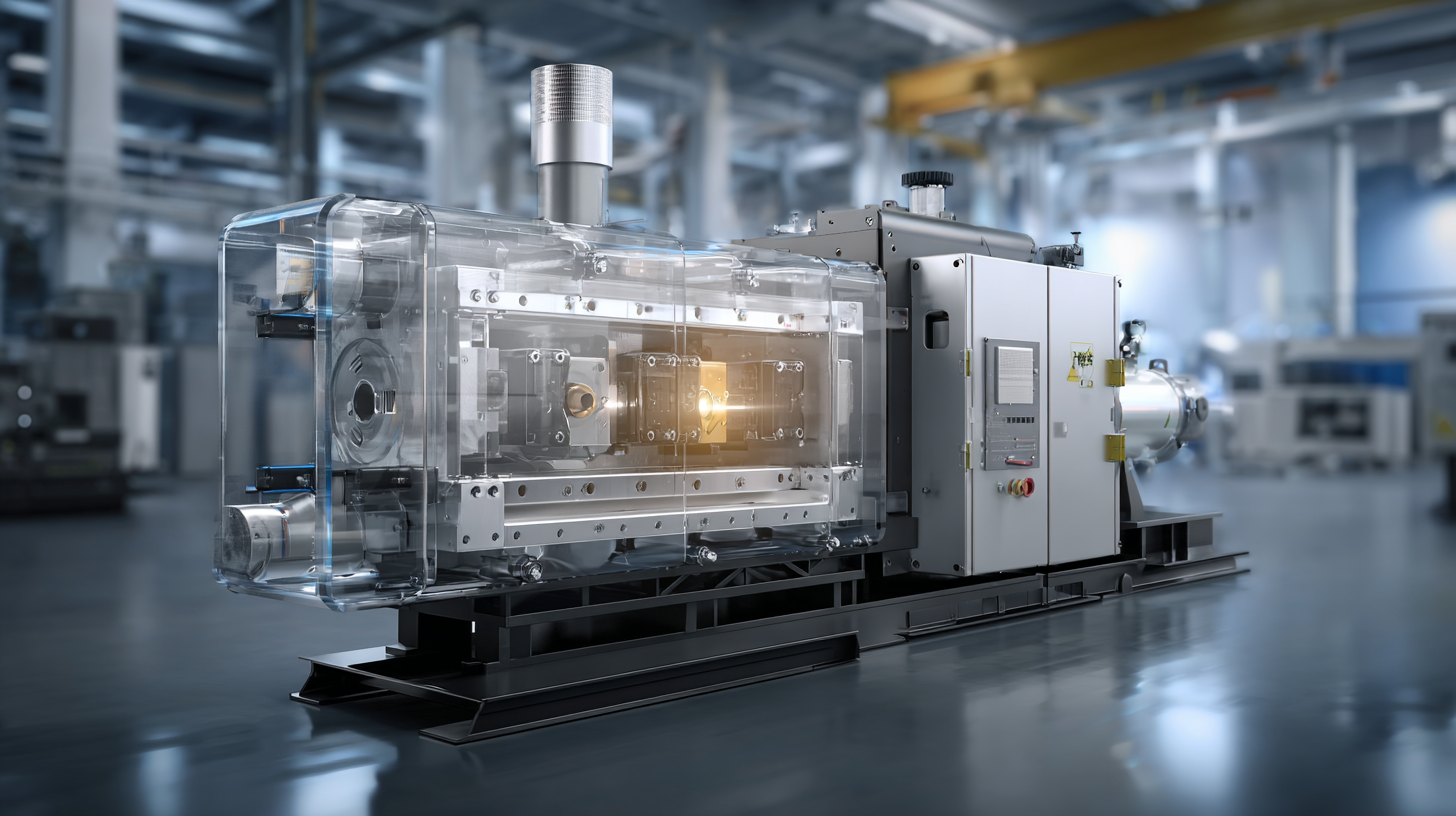

You know, the manufacturing world is constantly changing, and extruder technology is right at the heart of this big shift. Recent reports are pretty exciting — they say the global extrusion market might hit around $300 billion by 2025! That’s largely thanks to the growing demand for smarter, more innovative ways to process materials. One company that’s really making a difference here is FUTAI FILTERS DEPARTMENT at FUTAI MACHINERY CO., LTD. They started back in 2007 and have been pushing the boundaries with their filtration products used in all sorts of manufacturing processes. They’re experts when it comes to high-quality metal wire cloths, like stainless steel 304/316/316L, and they’re well-equipped to keep up with the latest in extruder tech. Their work helps make production more efficient while still sticking to industry standards. In this blog, we’ll take a look at how extruder technology is evolving and chat about how companies like FUTAI are really shaping what’s next for manufacturing through innovation and quality — pretty exciting stuff, right?

The Historical Context of Extruder Technology in Manufacturing

You know, the story of how extruder technology in manufacturing has developed is pretty fascinating and actually stretches back to the early 1800s. Back then, it was all pretty basic—manual work and simple tools—mostly making metal rods and the like. Those early days really set the stage for everything that was to come, especially as the Industrial Revolution kicked into gear and the push for mass production and efficiency started growing.

Fast forward a bit, and by the late 1800s and early 1900s, big changes started happening—thanks to electricity and better materials science. The invention of continuous extruders was a game-changer—it made it possible to produce more complex shapes and handle larger volumes, especially with plastics and rubber. New materials and improved tech didn’t just make products better and more consistent; they also opened up a ton of new uses across industries like automotive and packaging.

All this shows how extruder tech has been constantly evolving to keep up with what manufacturing needs—kind of like it’s been growing alongside us. And honestly, it’s exciting to think about where it might go next!

Key Innovations in Extruder Design Over the Decades

You know, over the years, extruder technology has really come a long way and totally changed how manufacturing works. Back in the day, these machines were pretty basic — just simple screw designs and mechanical parts that got the job done. But as industries grew and everyone started pushing for more efficiency, things got interesting. That’s when twin-screw extruders showed up. They’re a game-changer! They mix materials way better, crank out more product faster, and actually improve the quality of the materials being processed. It’s pretty amazing how much that shifted the game in polymer manufacturing.

Jump into the 2000s, and suddenly everyone’s talking about saving energy. So, new tech came out — smarter temperature controls and variable speed drives. These upgrades didn’t just make the machines more precise; they also helped cut down on energy use, which is a big plus for sustainability. Plus, with digital tech like IoT and machine learning coming into play, we can now monitor everything in real time and even predict problems before they happen. That helps keep those extruders running smoothly with minimal downtime. And as materials keep getting lighter and stronger, new design ideas keep popping up. All these tweaks mean extruder tech is still evolving to meet the ever-changing needs of manufacturing today.

The Role of Digital Transformation in Extruder Efficiency

You know, in today's manufacturing world, the way digital tech is stepping up extruder efficiency really can't be overlooked. As more industries jump on the smart tech bandwagon, their extruder operations are getting way more smooth and responsive. Things like IoT sensors and real-time data analytics now make it possible for manufacturers to keep a close eye on production happening right now — which means less downtime and way less waste. Using these tools, companies can fine-tune their processes, leading to better product quality and even cutting down on energy bills.

If you’re looking to boost your extruder game, a good tip is to implement predictive maintenance tech. These systems analyze how machines are performing and can even warn you about problems before they turn into big issues. It’s a smart way to prevent surprises, keep equipment running longer, and save money in the long run.

Another trick is to roll out an advanced manufacturing execution system, or MES — it gives everyone a clear picture of what's happening on the shop floor, so decisions are quicker and teams work better together.

And don’t forget about the cloud — moving your data there makes it super easy for everyone involved to access info whenever they need it. This kind of real-time collaboration helps make smarter decisions, and sparks new ideas. Overall, jumping into this digital world isn’t just a trend — it’s a real game-changer that can help your extruder productivity grow and keep you competitive out there.

Sustainability Trends: Eco-Friendly Extrusion Processes

You know, the extrusion industry is going through quite a shift these days. Sustainability is really taking center stage in how things are made now. Funny enough, recent reports show that about 30% of all plastic waste actually comes from manufacturing — that pretty much says we need to get greener, like, yesterday. If companies start using more eco-friendly extrusion tech, they can cut down their carbon footprints pretty significantly, all while making their processes more efficient. For example, using recycled materials in extrusion not only helps the environment but also cuts energy use by nearly 20%. That’s a win-win because it helps companies play by stricter environmental rules AND meet consumer demand for sustainable products.

Plus, newer methods like optimizing screw design and using energy-efficient heating systems are big game-changers. A 2022 industry report found that companies who adopted these tech upgrades saw energy consumption drop by as much as 40%. So, focusing on making better use of resources isn’t just good for the planet — it also means saving money in the long run. Overall, as the world pushes harder on sustainability, businesses that jump on the eco-friendly extrusion bandwagon will not only do their part for the environment but also set themselves up for long-term success. It’s pretty exciting stuff, honestly.

Envisioning Tomorrow: The Evolution of Extruder Technology in Manufacturing Process

This chart illustrates the trends in recycled material usage and energy efficiency improvement within extruder technology over the years from 2020 to 2024, highlighting the growing focus on sustainability in manufacturing processes.

Future Prospects: AI and Automation in Extruder Technology

Looking ahead into the world of extruder tech, one thing’s pretty clear — AI and automation are really shaking things up in manufacturing. It’s like having a superpower to boost precision and efficiency on the production line! With all these smarter systems doing predictive maintenance and monitoring in real-time, factories can run smoother and cut down on those frustrating downtimes we always complain about. Plus, tweaking extruder settings with intelligent tech means better, more consistent products – it’s a game changer.

It’s like having a superpower to boost precision and efficiency on the production line! With all these smarter systems doing predictive maintenance and monitoring in real-time, factories can run smoother and cut down on those frustrating downtimes we always complain about. Plus, tweaking extruder settings with intelligent tech means better, more consistent products – it’s a game changer.

That said, it’s not all smooth sailing. There’s a lot of talk about how this shift might affect workers. Automation’s arrival is expected to replace quite a few jobs, especially in assembly and production roles. For example, by 2025, Germany might see a pretty big dip in those traditional jobs because of more advanced robots and AI stepping in. This whole shift really highlights how important it is for workers to learn new skills and adapt to the changing landscape. We’re moving toward a future where human skills and AI work hand-in-hand, shaping the manufacturing industry in a whole new way.

Case Studies: Successful Implementation of Advanced Extruders in Industries

You know, with all the latest advancements in extruder tech, it’s really shaken up so many manufacturing fields. Processes are now way smoother, and the quality of products has just shot up. Take the packaging world, for example—many companies have started using twin-screw extruders to get better mixing and plasticization. The result? More consistent, high-quality films that look great. There’s this big food packaging firm that’s a perfect example—they jumped on the bandwagon and used these advanced extruders to create biodegradable packaging. Not only did it boost their production efficiency, but it also helped them step into more sustainable practices, which is a big deal since consumers are craving eco-friendly options these days.

And it’s not just packaging—automotive manufacturers have also seen game-changing results with specialized extruders. One leading car maker recently switched to a single-screw extruder, specifically designed for making lightweight polymer parts. This move helped make their vehicles lighter, which means better fuel economy. Plus, it opened doors to all kinds of intricate designs that traditional methods simply couldn’t handle. All in all, the adoption of this tech really shows how powerful advanced extruders can be—they’re playing a huge role in pushing innovation in all sorts of industries.

Enhancing Efficiency and Longevity: The Benefits of Stainless Steel Gas Filters with Metal Media

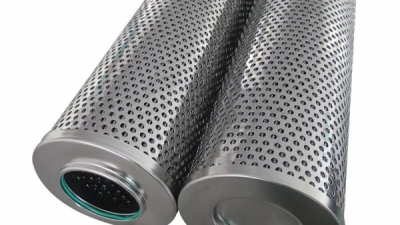

Stainless steel gas filters with metal media are revolutionizing the field of gas filtration by enhancing efficiency and ensuring longevity in various applications. These filters are specifically designed to handle a wide range of contaminants, making them ideal for industries where gas purity is paramount. The robust nature of stainless steel allows for effective particle filtration, physically trapping solid particles and particulate matter that could compromise equipment performance. Unlike traditional materials, stainless steel provides superior resistance to corrosion and wear, ensuring a longer lifespan and reduced maintenance needs.

Moreover, coalescing filtration is another critical feature of stainless steel gas filters. This method excels in removing liquid droplets or mists from gas streams, creating a cleaner product that protects downstream processes. By allowing tiny droplets to merge into larger ones, coalescing filters facilitate easier separation and drainage, significantly improving operational efficiency. The selection of stainless steel as a filter medium enhances the overall effectiveness of this approach, ensuring that gas remains free from harmful contaminants, ultimately leading to increased reliability and performance of equipment.

In conclusion, the integration of metal media in gas filtration systems not only addresses immediate filtration needs but also contributes to the long-term sustainability of industrial processes. As industries continue to push for higher efficiency and cleaner outputs, stainless steel gas filters stand out as a preferred solution, capable of meeting rigorous demands while enhancing the longevity of filtration systems.

FAQS

: Key advancements include the introduction of twin-screw extruders for better mixing and increased throughput, advanced temperature-control systems, variable speed drives for energy efficiency, and the integration of digital technologies like IoT and machine learning for real-time monitoring.

The focus on energy efficiency has led to the development of advanced temperature-control systems and variable speed drives that optimize the processing environment and reduce energy consumption, making manufacturing processes more sustainable.

Sustainability has become a central concern in the extrusion industry, with a push towards eco-friendly innovations to reduce plastic waste and lower carbon footprints in manufacturing processes.

Manufacturers can reduce their carbon footprint by integrating recycled materials into their extrusion processes and adopting technology that lowers energy consumption, such as advanced screw designs and energy-efficient heating systems.

Approximately 30% of all plastic waste originates from manufacturing processes, highlighting the need for sustainable practices in the industry.

Manufacturers that implemented advanced extrusion methods have reported up to a 40% reduction in energy usage, which supports environmental goals and drives cost savings.

Digital technologies, including IoT and machine learning, enable real-time monitoring and predictive maintenance, ensuring extruders operate at peak performance with minimal downtime.

Implementing eco-friendly extrusion processes not only supports sustainability but also drives cost savings through reduced energy consumption and optimized resource use.

Modern extruder design emphasizes lightweight and high-strength materials to meet the dynamic needs of contemporary manufacturing.

The use of advanced extrusion technologies, such as optimized screw designs and energy-efficient heating systems, enhances production efficiency while contributing to sustainability efforts.

Conclusion

So, I came across this blog titled "Envisioning Tomorrow: The Evolution of Extruder Technology in Manufacturing," and honestly, it's a pretty fascinating look at how extruder tech has evolved over the years. It walks you through the history, highlighting some really key innovations that have totally shaped the manufacturing scene we see today. Plus, it digs into how digital transformation is making extruders more efficient—kind of like giving them a tech boost—and also talks about the push towards more eco-friendly extrusion methods, which is pretty cool. The piece even looks ahead, imagining a future where AI and automation will take extruders to a whole new level, revolutionizing how things get made.

And here’s a little shoutout to FUTAI MACHINERY CO., LTD.—they’ve been in the game since 2007, mainly making filtration products, and they’re definitely right there, riding the wave of these tech advances. They’re well-known for their top-notch metal wire cloth, and they get how super important it is to stay on the cutting edge of extruder tech to improve what they do—whether that’s boosting quality or being more sustainable. It’s kind of a perfect mix of sticking to their roots but also embracing innovation, which helps them stay competitive and eco-conscious in today’s manufacturing world.

Related Posts

Blog Tags: