Ultimate Guide to Finding Quality Barmag Spare Parts for Your Textile Machinery

Table of Contents

- How to Identify Quality Barmag Spare Parts for Textile Machinery

- How to Assess Supplier Credibility for Barmag Parts

- How to Evaluate Compatibility of Spare Parts with Existing Machinery

- How to Compare Costs and Negotiating Terms for Barmag Parts

- How to Ensure Timely Delivery and Inventory Management of Spare Parts

- How to Maintain and Extend the Life of Barmag Spare Parts in Use

- Efficient Solutions for Industrial Filtration: The High Economic Gas-Liquid Filter Screen

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of textile machinery, having high-quality parts is more important than ever—especially for essential items like Barmag Spare Parts. Recent industry reports suggest that the global market for textile machinery could hit around $XX billion by 2025, and with more companies investing in quality maintenance, there's a growing buzz around reliable spare parts. After all, the success of textile production really depends on machinery uptime and efficiency. That’s why sourcing top-notch spare parts is so critical for keeping things running smoothly.

At FUTAI MACHINERY CO., LTD., we’ve been around since 2007, and we draw on years of manufacturing experience—particularly in filtration products—to meet the needs of the textile industry. We offer a variety of metal wire cloth options, including stainless steel 304/316/316L. Our focus on quality matches industry standards, so our clients can always count on getting the best Barmag Spare Parts to keep their operations on point.

How to Identify Quality Barmag Spare Parts for Textile Machinery

When you're trying to find quality Barmag spare parts for your textile equipment, the first thing to keep in mind is identifying what's legit. Do some digging to find reputable suppliers who really know their Barmag components—look for folks with good track records and solid customer reviews. Genuine parts manufacturers usually provide detailed specs and certifications that prove their quality. That way, you can be pretty confident the parts will fit well and help your machinery last longer and run more smoothly.

Also, take a close look at the material and craftsmanship of the parts. Good Barmag components are made from tough, durable materials that can handle the wear and tear of textile production. Check if the parts have a nice finish, smooth edges, and seem solid overall. If you want to be extra sure, it’s smart to buy directly from Barmag or authorized distributors. This not only makes sure you’re getting authentic parts but often comes with warranties and support, which is a big plus for peace of mind when making your investment.

How to Assess Supplier Credibility for Barmag Parts

Whenever you're hunting for Barmag spare parts for your textile machinery, trust me, the credibility of the supplier is a big deal. I mean, did you know that the global textile machinery market is expected to hit around USD 25 billion by 2026? That really puts into perspective how crucial reliable components are for keeping things running smoothly and avoiding headaches down the line. So, when you're evaluating suppliers, start by looking into their experience—those who’ve been around a while usually know their stuff and are more dependable. Plus, it's a good sign if they comply with international quality standards like ISO 9001; it shows they’re serious about delivering quality. A lot of industry folks, like those surveyed by the International Textile Manufacturers Federation, say they prefer suppliers who stick to these kinds of standards—that’s often linked directly to better operational results.

Also, don’t forget to check out client testimonials and case studies. They can give you a real feel for how well the supplier's parts perform in different settings. And of course, open and honest communication about how they source and manufacture their parts is key—because it builds trust and helps make sure you’re getting the good stuff, every time.

How to Evaluate Compatibility of Spare Parts with Existing Machinery

When you're on the hunt for quality spare parts for your Barmag textile machinery, it’s pretty important to check whether these parts actually fit with what you already have. Trust me, making sure they match up with the specs can really make a difference in how your machine runs and how long it lasts. But honestly, figuring this out is a bit of a learning curve; you need a solid understanding of both the replacement parts and your equipment’s needs.

A good tip? Always double-check the part numbers and specs—stick to reliable manufacturers to avoid any surprises. If you’re unsure, it’s smart to run some tests or get advice from an expert who knows their stuff. And don’t forget to peek at your machine’s manual. It usually has helpful info on compatible parts and performance standards, especially for those critical components that impact your operations.

On a similar note, thinking about the reliability of your gear is just as crucial—kind of like how medical equipment standards are really strict. Keeping an eye on how your machinery is performing and its overall condition can help you keep production smooth and avoid unnecessary downtime. With years of experience under our belt, FUTAI MACHINERY CO., LTD always stresses the importance of using high-quality materials—like stainless steel wire cloth—that can really boost the performance and compatibility of your spare parts. So, it’s all about making smart choices to keep things running smoothly.

How to Compare Costs and Negotiating Terms for Barmag Parts

When you're hunting for quality spare parts for textile machinery—especially Barmag parts—it's pretty important to know how to compare prices and negotiate good deals. Lately, industry reports have shown that sourcing parts from different parts of the world can really save you some cash, with price differences reaching as much as 30% between suppliers. So, taking the time to dig into the market and do your homework before making a purchase is definitely worth it.

And don’t underestimate the power of negotiating! A survey by the Textile Machinery Manufacturers' Association found that companies who use structured negotiation strategies can often get about 15% better prices than those just accepting standard offers. Things like bulk purchasing or building long-term relationships with suppliers can lead to extra discounts too. By keeping these tips in mind and doing a little research, textile manufacturers can get the Barmag spare parts they need without sacrificing quality—or blowing their budgets.

Ultimate Guide to Finding Quality Barmag Spare Parts for Your Textile Machinery - How to Compare Costs and Negotiating Terms for Barmag Parts

| Part Name | Quality Rating | Average Cost ($) | Supplier Availability | Negotiation Tips |

|---|---|---|---|---|

| Spinner Frame | High | 250 | In Stock | Negotiate bulk buys |

| Yarn Guide | Medium | 150 | Limited | Ask for discounts on quantities |

| Tension Controller | High | 300 | Available | Compare prices from multiple suppliers |

| Coiler | Low | 100 | In Stock | Check for refurbished options |

| Heat Gun | Medium | 200 | Available | Negotiate shipping costs |

How to Ensure Timely Delivery and Inventory Management of Spare Parts

When it comes to making sure that Barmag spare parts for textile machines get delivered on time and that inventory is managed smoothly, companies really need to adopt smart strategies to keep their supply chains running well. According to a report by the Textile Machinery Association, about 73% of textile manufacturers say that having spare parts available when needed is a huge deal for keeping machines running efficiently. This just goes to show how important it is to build solid relationships with suppliers who can deliver quality parts quickly—and reliably.

Here at FUTAI MACHINERY CO., LTD., we totally get that good inventory management is key to minimizing costly downtime within textile production. By using high-tech tracking systems and keeping just the right amount of stock on hand, businesses can cut down on the wait times for spare parts significantly. Plus, a study from the International Textile Manufacturer Federation found that companies that stay proactive with their inventory end up experiencing about 20% fewer disruptions in their operations. Investing in top-notch filtration products—like our stainless steel wire cloth—not only boosts machine performance but also helps improve overall manufacturing efficiency. Sometimes, little things like that make a big difference!

Quality Barmag Spare Parts Inventory Management

How to Maintain and Extend the Life of Barmag Spare Parts in Use

Taking care of your Barmag spare parts and giving them a little extra love isn't just about routine maintenance — it's actually key to keeping your textile machinery running smoothly and lasting longer. Think of regular check-ups as saving you from those pesky, expensive breakdowns and keeping productivity steady. Industry folks say that with regular inspections and swapping out worn parts on time, you can boost the lifespan of your machine components by up to 30%. Things like lubrication, double-checking alignment, and making sure there's no dust or debris building up are all simple steps that make a big difference.

Here’s a little tip: keep a detailed service log. Trust me, it’s super helpful to track what’s been done and catch patterns in wear and tear early. That way, you can plan replacements before things go haywire. Also, following the manufacturer’s recommended timelines for replacing parts really helps prevent surprise failures, saving you headaches (and money).

And hey, never underestimate the importance of using good quality spare parts. Cheap, low-grade stuff might seem like a deal at first, but in the long run, it can cause more damage and make your machinery work harder than it should. Industry reports show that investing in top-quality parts can reduce maintenance costs by up to 20%. Plus, training your team regularly on the best ways to maintain and operate these parts is a smart move — fresh knowledge means smoother running and longer-lasting machinery.

Here's a pro tip: schedule regular training sessions for your crew. Keeping everyone updated on maintenance practices isn’t just good for operation — it can extend the life of your parts and save you hassle down the line.

Efficient Solutions for Industrial Filtration: The High Economic Gas-Liquid Filter Screen

The efficient management of gas and liquid phases in industrial processes is crucial for enhancing operational performance and compliance with environmental standards. A highly effective solution for this challenge is the gas-liquid filter screen, a specialized filtration device designed to separate liquid droplets or mist from gas streams. These screens are particularly prevalent in applications such as scrubber systems, distillation columns, and gas treatment plants, where the integrity and quality of the gas phase must be maintained.

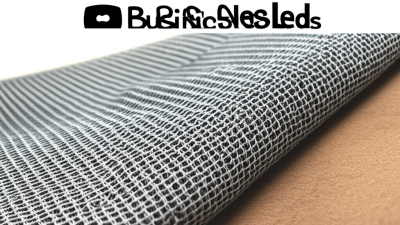

Constructed from multiple layers of woven wire mesh, gas-liquid filter screens are engineered with specific spacings and designs tailored to optimize the capture of liquid droplets. The materials used, often stainless steel, not only provide durability but also ensure resistance to corrosion in demanding industrial environments. According to recent industry reports, the market for gas-liquid filtration systems is projected to grow at a CAGR of over 5% from 2021 to 2028, underscoring the increasing recognition of their vital role in process optimization and environmental sustainability.

The efficacy of gas-liquid filter screens is evident in their ability to prevent liquid carryover, which can cause significant damage to downstream equipment and lead to costly downtimes. Moreover, adhering to stringent environmental regulations necessitates robust filtration systems to minimize emissions and ensure operational compliance. By incorporating advanced gas-liquid filter screens, industries can not only enhance productivity but also contribute to a cleaner and more sustainable operational ethos.

FAQS

: Start by researching reputable suppliers with a proven track record and positive testimonials. Look for detailed specifications and certifications from genuine manufacturers to ensure proper fit and quality.

Quality Barmag parts are typically made from durable materials that can withstand the demands of textile production. Inspect for consistent finishes, smooth edges, and robust structural integrity.

Consider sourcing spare parts directly from Barmag or authorized distributors to guarantee authenticity and often receive warranties or support services.

Evaluate the supplier's industry experience, compliance with international quality standards (like ISO 9001), and look for client testimonials and case studies that evidence the reliability of their components.

Key practices include regular inspections, timely replacements, lubrication, alignment checks, and ensuring parts are free from debris and contaminants.

A detailed service log helps track the condition of your spare parts, identify patterns in wear and tear, and enable proactive maintenance to prevent costly downtime.

Using top-grade spare parts can reduce maintenance costs by as much as 20% and increase the lifespan of machinery components by up to 30%.

Yes, regular training for staff on best practices for maintenance and operation can contribute to the longevity of spare parts and improve overall operational efficiency.

Conclusion

When it comes to keeping your textile machinery running smoothly, finding good quality Barmag spare parts is pretty much essential. It all starts with making sure you're getting genuine components—things like checking the material quality and matching manufacturer specs. Picking a trustworthy supplier is just as important; you want someone with a solid track record and who stand behind their products with warranties. Oh, and don’t forget to double-check if the parts will work perfectly with what you already have—nothing worse than dealing with unexpected hiccups on the shop floor.

On top of that, doing some price comparisons and knowing how to negotiate can save you a decent chunk of change. Timely delivery and smart inventory management are key, too, so your workflow doesn’t hit any snags. And of course, taking care of your Barmag parts properly—regular maintenance and proper handling—can really extend their lifespan and keep things ticking along smoothly. Companies like FUTAI MACHINERY CO., LTD., with tons of experience in making filtration products, show just how important it is to go for quality craftsmanship and reliability when sourcing these critical parts for your textile machinery.

Related Posts

-

How to Maximize Production Efficiency with Barmag Spare Parts Insights and Best Practices

-

10 Essential Benefits of Pre Filter Candle: Enhance Your Air Quality Management Strategy

-

Ultimate Guide to Choosing the Right Melt & Polymer Filters for Your Industry Needs

-

Barmag Innovations Showcased at the 138th China Import and Export Fair 2025

-

5 Best Reasons to Choose Mesh Pack for Your Business Needs

-

5 Essential Tips for Mastering Poy Spinning Techniques

Blog Tags: